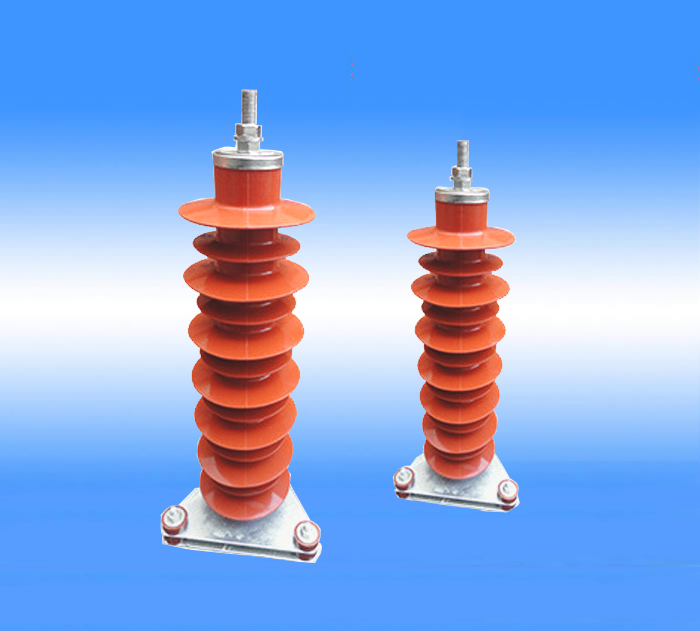

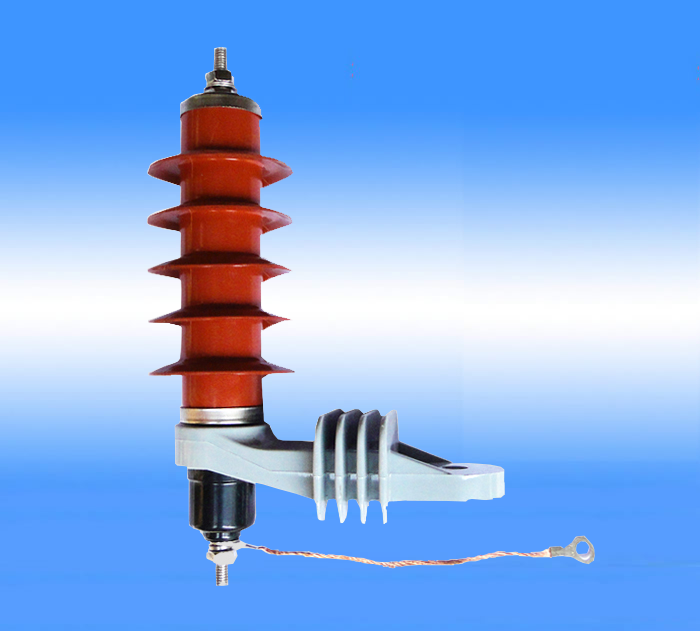

HY5WZ-17-45 distribution type zinc oxide lightning arrester manufacturer

Brand: lixiong

- Description

- Installation

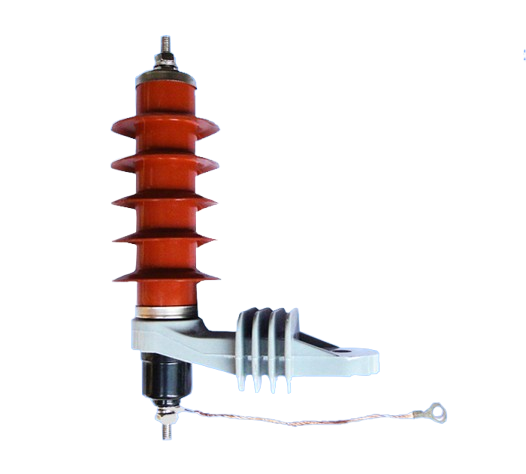

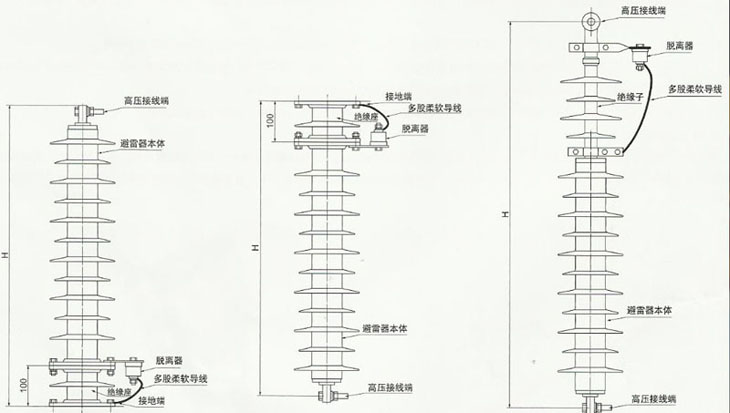

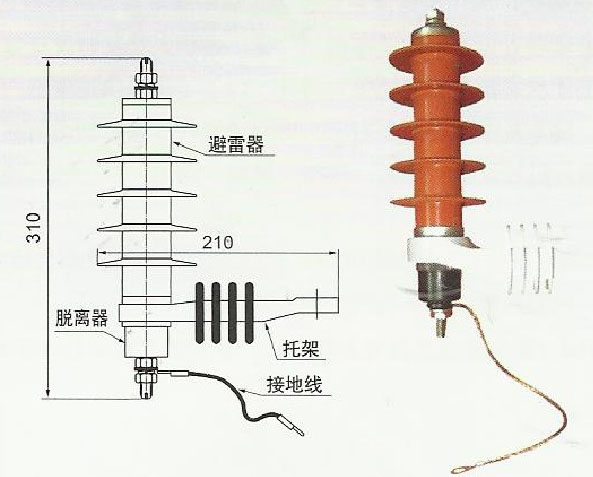

The release device for lightning arrester is an accessory of the lightning arrester and is used in series with the lightning arrester. The purpose is to use the power frequency short-circuit current flowing through the lightning arrester to make the disconnector operate, so that the grounding end of the disconnector will be automatically disengaged, and the arrester will exit the system operation, prevent the accident from further expanding, and give a visibility of the faulty lightning arrester to facilitate maintenance personnel to discover the fault points in time for maintenance and replacement. When the lightning arrester is in normal operation, the releaser is in an AC-conducting state and does not affect the original working state of the system and the protection characteristics of the lightning arrester, ensuring the normal operation of the system and making the lightning arrester truly meet the "maintenance-free" usage requirements. Due to this excellent characteristic of the release device, various types of lightning arresters operating in the power grid have been used in foreign countries, such as Europe, America, Japan and Southeast Asian countries and regions. With the rapid development of national power construction and the safety requirements for power systems, the use of disconnectors has been gradually promoted in power generation, power stations, railways, civil aviation, communications, mines and other important power supply sites in China.

The standards implemented in the production of disconnectors are GB11032-200 "Accessless Metal Oxide Lightning Arresist" and IEC.C62 "Switching Lightning Arresist Requirements for Distribution Lightning Arresist". The use environment requirements of the release device are the same as those of the lightning arrester.

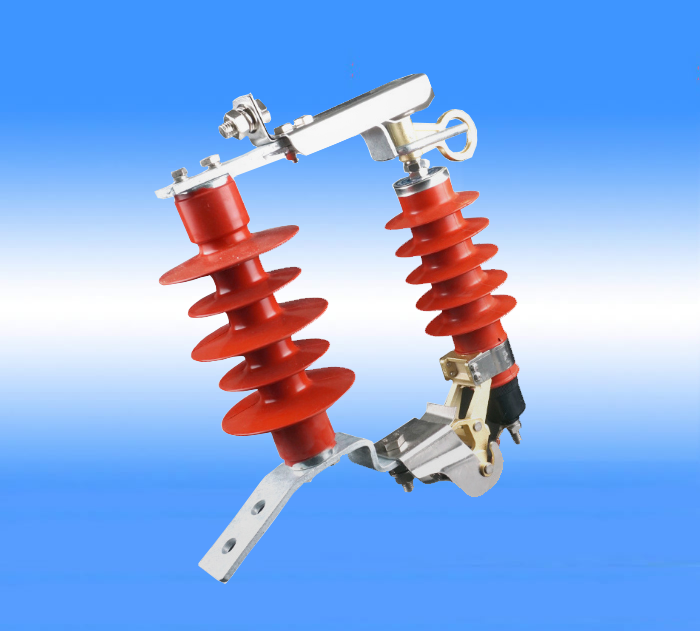

1. Thermal burst releaser

A. Wide range of operating current: Combined with the characteristics of China's power grid, it can be disengaged at a large industrial frequency fault current (>50A) or at a small industrial frequency fault current (50mA);

C. High mechanical strength and good sealing performance: The disengaged has high mechanical strength and good sealing performance before it is disengaged. The tensile strength of RBT-3 type >2000N, the tensile strength of RBT-4 type >4000N, the RBT-3 type disconnector can be used with lightning arresters below 35KV, and the RBT-4 type disconnector can be used with 35~220kv lightning arresters.

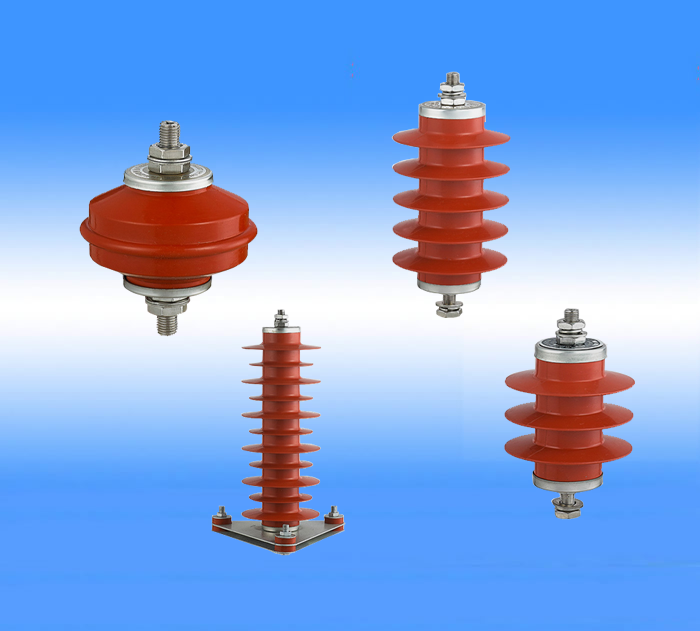

The hot melt releaser uses the power frequency short circuit current flowing through the failure arrester to fuse the low-temperature alloy melt in the releaser to achieve the purpose of disengagement. Therefore, the disengagement time of the hot melt releaser is longer than that of the hot burst releaser, and the disengagement time of 50mA~5A is 0.8~1.9 minutes. However, when the hot melt releaser disengages, there will be no explosion sound, no explosion vibration or explosion debris, and there will be no impact on the installation environment.

The standards implemented in the production of disconnectors are GB11032-200 "Accessless Metal Oxide Lightning Arresist" and IEC.C62 "Switching Lightning Arresist Requirements for Distribution Lightning Arresist". The use environment requirements of the release device are the same as those of the lightning arrester.

1. Thermal burst releaser

A. Wide range of operating current: Combined with the characteristics of China's power grid, it can be disengaged at a large industrial frequency fault current (>50A) or at a small industrial frequency fault current (50mA);

C. High mechanical strength and good sealing performance: The disengaged has high mechanical strength and good sealing performance before it is disengaged. The tensile strength of RBT-3 type >2000N, the tensile strength of RBT-4 type >4000N, the RBT-3 type disconnector can be used with lightning arresters below 35KV, and the RBT-4 type disconnector can be used with 35~220kv lightning arresters.

The hot melt releaser uses the power frequency short circuit current flowing through the failure arrester to fuse the low-temperature alloy melt in the releaser to achieve the purpose of disengagement. Therefore, the disengagement time of the hot melt releaser is longer than that of the hot burst releaser, and the disengagement time of 50mA~5A is 0.8~1.9 minutes. However, when the hot melt releaser disengages, there will be no explosion sound, no explosion vibration or explosion debris, and there will be no impact on the installation environment.

4. Use and size of the release device

Request a Quote

We will deliver a solution and quote that best suits your business needs